Let us begin with the industries that process fibres.

The weaving of linen, wool, cotton and silk fabrics, galloons, etc., was organised everywhere in Russia as follows (before the appearance of large-scale machine industry). The industry was headed by big capitalist workshops employing tens and hundreds of wage-workers; the owners of these workshops, possessing sizable capital, undertook the large-scale purchase of raw material, partly working it up in their own establishments, and partly giving out yarn and warp to small producers (workroom owners, middlemen,[88], peasant-“handicraftsmen” etc.) who wove the cloth at home or in small workshops at piece rates. The work itself was done by hand, and the following operations were distributed among the workers: 1) yarn-dyeing; 2) yarn-winding (very often women and children specialised in this operation); 3) yarn-fixing (“fixers”); 4) weaving; 5) weft-winding for weavers (bobbin hands, mostly children). Sometimes in the big workshops there were special “threaders” (who threaded the warp through the eyes of the batten and reed.)[1] of labour is usually applied, not only to single operations, but to wares, that is, the weavers specialise in producing various sorts of cloth. The selection of some operations to be done in the home does not, of course, make any change whatever to the economic structure of this type of industry. The workrooms or homes where the weavers work are simply external departments of the manufactory. The technical basis of such industry is hand production with extensive and systematic division of labour; from the economic point of view we see here the formation of large capital which controls the purchase of raw materials and the sale of wares on an extremely extensive (national) market, and under whose complete sway are a mass of proletarian weavers; a few large establishments (manufactories in the narrow sense of the term) dominate a mass of small ones. Division of labour leads to the emergence of specialist artisans from among the peasantry; non-agricultural centres of manufacture arise, such as the village of Ivanovo in Vladimir Gubernia (in 1871 it became the town of Ivanovo-Voznesensk and is now a centre of large-scale machine industry), the village of Velikoye in Yaroslavl Gubernia, and many other villages in Moscow, Kostroma, Vladimir and Yaroslavl gubernias, which have now turned into factory towns.[2] In our economic literature and statistics the industry organised in this way is usually split up into two parts: peasants who work in their homes, or in not particularly big workrooms, workshops, etc., are classed under “handicraft” industry, while the bigger workrooms and workshops are placed among the “factories and works” (and, moreover, quite fortuitously, since no definitely established and uniformly applied rules exist as to the separation of small establishments from big ones, of workrooms from manufactories, of workers occupied in their homes from workers occupied in the workshop of the capitalist).[3] Naturally, such classification, which places some wage-workers on one side, and some masters who hire these very wage-workers (in addition to the workers in their establishments) on the other, is nonsense from the scientific viewpoint.

Let us illustrate this by detailed data regarding one of the “handicraft weaving” industries, namely, silk weaving in Vladimir Gubernia.[4] The “silk industry” is a typical specimen of capitalist manufacture. Hand labour prevails. Of the total number of establishments the small ones constitute the majority (179 out of 313, or 57% of the total, have from 1 to 5 workers), but in greater part they are not independent and are far behind the big ones in their significance to the industry as a whole. Establishments with 20 to 150 workers constitute 8% of the total (25), but in them 41.5% of the aggregate number of workers are concentrated, and they account for 51% of the total output. Of the total number of workers in the industry (2,823) there are 2,092 wage-workers, i.e., 74.1%. “On the job we meet with division of labour both in wares and in individual operations.” Weavers are rarely able to make both “velvet” and “satin” (the two principal lines in this trade). “The division of labour into separate operations within the workshop is most strictly practised only in the big factories” (i.e., manufactories) “that employ wage-workers.” The fully independent proprietors number only 123, who alone buy the raw materials themselves and sell the finished article; they have 242 family workers and “employ 2,498 wage-workers, who in greater part are paid by the piece,” a total, consequently, of 2,740 workers, or 97% of the aggregate number of workers. It is thus clear that the distribution by these manufactory owners, through the medium of “middle-men” (workroom owners), of work to be done in the home is no special form of industry at all, but is merely one of the operations of capital in manufacture. Mr. Kharizomenov rightly observes that the “mass of small establishments (57%) alongside the small number of big ones (8%), and the insignificant number of workers employed per establishment (7 1/2) conceal the true character of the trade” (loc. cit., 39). The specialisation characteristic of manufacture is seen here clearly in the separation of the industrialists from agriculture (the land is abandoned, on the one hand by the impoverished weavers, and on the other by the big manufactory owners) and in the formation of a special type of industrial population, who live much more “decently” than do the agriculturists, and look down upon the muzhik (loc. cit., 106). Our factory statistics have always registered only a very casually selected fraction of this industry.[5]

The “galloon industry” in Moscow Gubernia is capitalist manufacture organised in a quite analogous fashion.[6] Such precisely is the case with regard to the printed calico industry in Kamyshin Uyezd, Saratov Gubernia. According to the Directory for 1890, there were here 31 “factories” with 4,250 workers and output totalling 265,000 rubles, while according to the List there was one “work distributing office” with 33 workers in the establishment and an output totalling 47,000 rubles. (In other words, in 1890 workers employed in the establishment and on the side were lumped together!) According to local investigators, in 1888 nearly 7,000 looms were engaged in producing printed calico,[7] an output totalling 2 million rubles, and “the whole business is run by a few manufacturers,” who employ “handicraftsmen” too, including children of 6 and 7 years of age for a payment of 7 to 8 kopeks per day (Reports and Investigations, Vol. I).[8] And so forth.

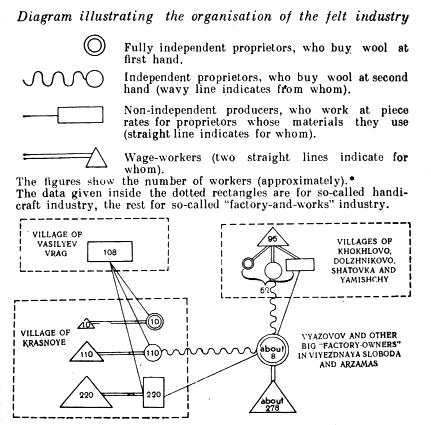

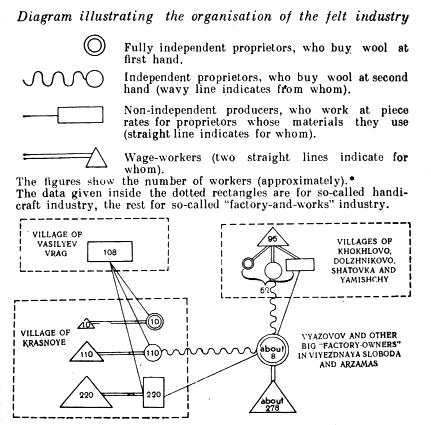

To judge by official factory statistics, felt production shows a very poor development of “capitalism”: in all European Russia there are altogether 55 factories, with 1,212 workers and an output totalling 454,000 rubles (Directory for 1890). But these figures merely show a casually picked fragment of a widely developed capitalist industry. Nizhni-Novgorod Gubernia occupies first place for the development of “factory” felt production, and in that gubernia the principal centre of the industry is the town of Arzamas and the suburb Viyezdnaya Sloboda (where there are 8 “factories” with 278 workers and an output totalling 120,000 rubles; in 1897 there were 3,221 inhabitants; and in the village of Krasnoye, 2,835). It is in the environs of these centres that “handicraft” felt-making is developed, in some 243 establishments, employing 935 workers, with an output totalling 103,847 rubles (Transactions of the Handicraft Commission, V). To illustrate clearly the economic organisation of felt-making in this district, let us try the graphic method and indicate by specific symbols the producers who occupy special places in the general structure of the industry.

It is clear, therefore, that the separation of “factory” and “handicraft” industry is purely artificial, that what we have before us is a single and integral structure of industry which fully fits into the concept of capitalist

(approximately)[9]

manufacture.[10] From the technical aspect it is hand production. The organisation of the work is that of co-operation based on division of labour, which is here observed in two forms: as to wares (some villages specialise in plain felt, others in boots, hats, socks, etc.), and as to individual operations (for example, the whole village of Vasilyev Vrag shapes hats and socks for the village of Krasnoye, where the semi-prepared article is finished, etc.). This is capitalist co-operation, for it is headed by big capital, which has created large manufactories and has brought under its sway (by an intricate web of economic relations) a mass of small establishments. The overwhelming majority of the producers have been transformed into workers performing one operation and producing for entrepreneurs under extremely insanitary conditions.[11] The long standing of the industry and the fully established capitalist relations result in the separation of the industrialists from agriculture: in the village of Krasnoye agriculture is in utter ruin, and the life of the inhabitants differs from that of the agricultural population.[12]

Quite analogous is the organisation of the felt industry in a number of other districts. In 363 village communities of Semyonov Uyezd in the same gubernia, the industry in 1889 was carried on by 3,180 households, with 4,038 persons working. Of 3,946 workers, only 752 worked for the market, 576 were wage-workers and 2,618 worked for masters on the basis, in greater part, of using the latter’s materials; 189 households gave out work to 1,805 households. The big owners have workshops with as many as 25 wage-workers, and buy wool to a value of some 10,000 rubles per year.[13] The big owners are called thousanders ; their turnover runs to from 5,000 to 100,000 rubles; they have their own wool warehouses, and their own booths for the sale of wares.[14] For Kazan Gubernia the List gives 5 felt “factories,” with 122 workers and an output totalling 48,000 rubles, as well as 60 outside workers. Evidently the latter are also included among the “handicraftsmen,” concerning whom we read that they often work for “buyers-up” and that there are establishments having 60 workers.[15] Of 29 felt “factories” in Kostroma Gubernia, 28 are concentrated in Kineshma Uyezd, and have 593 workers employed in the establishments and 458 outside (List, pp. 68-70; two of the enterprises have only outside workers. Steam-engines already appear). From the Transactions of the Handicraft Commission (XV) we learn that out of a total of 3,908 wool-carders and felt-makers in this gubernia, 2,008 are concentrated in Kineshma Uyezd. The Kostroma felt-makers are in greater part dependent or work for wages in extremely insanitary workshops.[16] In Kalyazin Uyezd, Tver Gubernia, we find, on the one hand, that home work is done for “factory owners” (List, 113), and, on the other, that precisely this uyezd is a centre of “handicraft” felt-makers; as many as 3,000 of them come from this uyezd, passing through the wasteland called “Zimnyak” (in the 60s it was the site of Alexeyev’s cloth mill), and forming “an enormous labour market of wool-carders and felt-makers.”[17] In Yaroslavl Gubernia outside work for “factory owners is a]so done” (List, 115) and there are “handicraftsmen” who work for merchant proprietors, using the latter’s wool, etc.

Above we gave statistics for the hat industry of Moscow Gubernia.[18] They show that two-thirds of the total output and of the total number of workers are concentrated in 18 establishments, which have an average of 15.6 wage-workers.[19] The “handicraft” hat-makers perform only part of the hat-making operations: they make the shapes, which are sold to Moscow merchants who have their own “finishing establishments”; on the other hand, “clippers” (women who clip the down) work at home for the “handicraft” hat-makers. Thus, all in all, we find here capitalist co-operation based on division of labour and entangled in a whole network of diverse forms of economic dependence. In the centre of the industry (the village of Klenovo, Podolsk Uyezd) the separation of the industrialists (mainly wage-workers) from agriculture[20] is clearly to be seen, together with a rise in the level of the population’s requirements: they live “more decently,” dress in calico and even in cloth, buy samovars, abandon ancient customs, etc., thereby evoking the bitter complaints of the local admirers of old times.[21] The new era even occasioned the appearance of migratory hat-makers.

A typical example of capitalist manufacture is the cap industry in the village of Molvitino, Bui Uyezd, Kostroma Gubernia.[22] “The principal . . . occupation in the village of Molvitino and in . . . 36 hamlets is the cap industry.” Agriculture is being abandoned. Since 1861 the industry has greatly developed; sewing-machines have become widely used. In Molvitino 10 workshops are busy all year round with 5 to 25 male and 1 to 5 female workers each. “The best workshop . . . has a turnover of about 100,000 rubles per annum.”[23] Work is also distributed to homes (for example, materials for the crowns are made by women in their homes). Division of labour cripples the workers, who work under the most insanitary conditions and usually contract tuberculosis. The lengthy existence of the industry (for over 200 years) has produced highly skilled craftsmen; the Molvitino craftsmen are known in the big cities and in the remote outer regions.

The centre of the hemp industry in the Medyn Uyezd, Kaluga Gubernia, is the village of Polotnyani Zavod. This is a large village (according to the census of 1897 it had 3,685 inhabitants) with a population that is landless and highly industrial (over 1,000 “handicraftsmen”); it is the centre of the “handicraft” industries of Medyn Uyezd.[24] The hemp industry is organised in the following way: the big proprietors (of whom there are three, the biggest being Yerokhin) have workshops employing wage-workers and circulating capital of more or less considerable dimensions for purchasing raw materials. The hemp is combed in the “factory,” spun by spinners in their homes, and twisted both in the factory and in the home. It is warped in the factory and woven both in the factory and in the home. In 1878 a total of 841 “handicraftsmen” was counted in the hemp industry; Yerokhin is considered to be both a “handicraftsman” and a “factory owner,” employing 94-64 workers in 1890 and in 1894-1895; according to Reports and Investigations (Vol. II, p.187), “hundreds of peasants” work for him.

In Nizhni-Novgorod Gubernia, the rope industry is also centred in non-agricultural industrial villages, Nizhni Izbylets and Verkhni Izbylets in the Gorbatov Uyezd.[25] According to Mr. Karpov (Transactions of the Handicraft Commission, Vol. VIII), the Gorbatov-Izbylets district is one large rope-making area; part of the inhabitants of the town of Gorbatov are also engaged in the industry, and the villages of Verkhni Izbylets and Nizhni Izbylets are, in fact, “almost part of the town of Gorbatov”; the inhabitants live like townspeople, drink tea every day, wear clothing bought in the shops, and eat white bread. Altogether, as many as two-thirds of the inhabitants of 32 villages are engaged in the industry, a total of 4,701 working (2,096 men and 2,605 women) with an output of about 1 1/2 million rubles. The industry has been in existence for nearly 200 years, and is now declining. It is organised as follows: all work for 29 proprietors, using the latter’s materials, are paid by the piece, are “totally dependent upon the proprietors” and work from 14 to 15 hours a day. According to Zemstvo statistics (1889) the industry employs 1,699 male workers (plus 558 females and males of non-working age). Of 1,648 working only 197 work for sale, 1,340 work for proprietors[26] and 111 are wage-workers employed in the workshops of 58 proprietors. Of 1,288 allotment households, only 727, or a little over half, cultivate all their land themselves. Of 1,573 allotment-holding working persons, 306, or 19.4%, do not engage in agriculture at all. Turning to the question as to who these “proprietors” are, we must pass from the sphere of “handicraft” industry to that of “factory” industry. According to the List for 1894-95 there were two rope factories there, with 231 workers employed on the premises and 1,155 working outside, with an output totalling 423,000 rubles. Both these establishments have installed motors (which they did not have either in 1879 or in 1890), and we therefore clearly see here the transition from capitalist manufacture to capitalist machine industry, and the transformation of “handicraft” work distributors and buyers-up into real factory owners.

In Perm Gubernia the handicraft census of 1894-95 registered 68 peasant rope-and-string yards, with 343 workers (of whom 143 were hired) and an output totalling 115,000 rubles.[27] These small establishments are headed by big manufactories, which are reckoned together, viz.: 6 owners employ 101 workers (91 hired) and have an output totalling 81,000 rubles.[28] The system of production in these big establishments may serve as the most striking example of “serial manufacture” (as Marx calls it[89]), i.e., the sort of manufacture in which different workers perform different consecutive operations in working up the raw material: 1) hemp scutching; 2) combing; 3) spinning; 4) coiling; 5) tarring; 6) winding on drum; 7) passing threads through perforated board; 8) passing threads through iron bush; 9) stranding of plaits, twisting and gathering of ropes.[29]

The organisation of the hemp industry in Orel Gubernia is evidently similar: from among the considerable number of small peasant establishments big manufactories emerge, principally in the towns, and are included among the “factories and works” (according to the Directory for 1890 there were in Orel Gubernia 100 hemp-scutching factories, with 1,671 workers and an output totalling 795,000 rubles). The peasants work in the hemp industry “for merchants” (probably for the very same manufacturers), using the latter’s materials, at piece rates, the work being divided up into special operations: “scutchers” scutch the hemp; “spinners” spin it; “bearders” trim it, “wheelmen” turn the wheel. The work is very hard; many contract consumption and “rupture.” The dust is so thick that “unless accustomed you will not stay in it for a quarter of an hour.” The work is done in ordinary sheds from dawn to dusk, from May to September.[30]

The most typical example of capitalist manufacture in this sphere is the chest-making industry. According to the data, for instance, of the Perm investigators, “this industry is organised as follows: a few big proprietors, owning workshops that employ wage-workers, purchase materials, partly make the wares on their own premises, but mainly give out material to small workshops making parts, and in their own shops assemble them and, after finishing, send the ready article to market. Division of labour . . . is employed on the job extensively: the making of the entire chest is divided into ten or twelve operations, each separately performed by handicraftsmen. The organisation of the industry consists in the combination of workers performing one operation (Teilarbeiter, as they are called in Das Kapital ) under the command of capital.”[31] This is heterogeneous manufacture (heterogene Manufaktur, as Marx calls it[90]), in which the different workers do not perform consecutive operations in turning the raw material into the product, but make the various parts of the product, which are afterwards assembled. The preference of the capitalists for the domestic work of “handicraftsmen” is to be explained partly by the above mentioned character of manufacture, and partly (and mainly) by the cheaper labour of the home workers.[32] Let us observe that the relatively big workshops in this industry are sometimes also included among “factories and works.”[33]

In all probability, the chest-making industry is organised similarly in Vladimir Gubernia, in Murom Uyezd where, according to the List, there are 9 “factories” (all hand-operated), with 89 workers on the premises and 11 outside, and an output totalling 69,810 rubles.

The carriage industry, in Perm Gubernia, for example, is organised on similar lines: from among the mass of small establishments there emerge assembly workshops employing wage-workers; the small handicraftsmen are workers who make parts of the carriages both out of their own materials, and out of materials supplied by the “buyers-up” (i.e., owners of the assembly workshops.)[34] We read about the Poltava “handicraft” carriage builders that in the suburb of Ardon there are workshops that employ wage-workers and also distribute work to homes (the bigger masters having as many as 20 outside workers).[35] In Kazan Gubernia, division of labour as to wares is to be observed in the building of town carriages: some villages specialise in sleighs, others in wheeled vehicles, etc. “The town carriages, completely assembled in the villages (but without the metal work, wheels or shafts), are sent to Kazan merchant customers, who in turn send them to blacksmiths for the metal work. The carriages are then sent back again to the shops and workshops in the town, where they are finished off, i.e., are upholstered and painted. . . . Kazan, where town carriages were formerly iron-mounted, gradually passed this work on to handicraftsmen, who work at home for a smaller payment than do the town craftsmen....”[36] Hence, capital prefers to distribute work to home workers because this reduces the cost of labour-power. The organisation of the carriage industry, as is evident from the data quoted, constitutes, in the majority of cases, a system of handicraftsmen making parts, who are under the sway of capital.

The large industrial village of Vorontsovka, Pavlovsk Uyezd, Voronezh Gubernia (9,541 inhabitants in 1897), constitutes, as it were, a single manufactory of wooden articles (Transactions of the Handicraft Commission, etc., Vol. IX, article by Rev. M. Popov). Over 800 houses are engaged in the industry (as well as some households in the suburb of Alexandrovka, which has over 5,000 inhabitants). They make carts, tarantasses, wheels, chests, etc., to a total of about 267,000 rubles. Less than one-third are independent masters; hired workers in masters’ workshops are rare.[37] The majority work to order for peasant merchants at piece rates. The workers are in debt to the proprietors and are worn out by arduous toil: the people are growing feebler. The inhabitants of the suburb are industrial, not of the rural type, and scarcely engage in agriculture at all (except to work vegetable plots), since their allotments are miserably small. The industry has been long in existence, diverting the population from agriculture and increasingly widening the rift between the rich and the poor. The people subsist on meagre food; they dress “more smartly than before,” “but beyond their means,” in clothing that is entirely bought. “The population has succumbed to the spirit of industry and trade.” “Nearly all who have no craft carry on some trading. . . . Under the influence of industry and trade, the peasant has, generally speaking, become more unreserved, and this has made him more developed and resourceful.”[38]

The celebrated wooden-spoon industry of the Semyonov Uyezd, Nizhni-Novgorod Gubernia, is close to capitalist manufacture in its organisation. True, there are no big workshops standing out from among the mass of small workshops and dominating them, but we find a deeply-rooted division of labour and the complete subjection of the mass of part-job workers to capital. Before it is ready, the spoon passes through no less than 10 hands, the buyers-up getting some of the operations done by specially hired workers or giving them out to specialist workers (for example, for varnishing); some of the villages specialise in particular operations (for example, the village of Dyakovo specialises in spoon finishing to the order of the buyer-up, at piece rates; the villages of Khvostikovo, Dianovo and Zhuzhelka specialise in varnishing, etc.). The buyers-up purchase the timber wholesale in the Samara and other gubernias, where they send parties of hired workers; they own warehouses for raw material and manufactured goods, supply the most valuable material to handicraftsmen for processing, etc. The mass of workers doing part jobs merge into a single, complex mechanism of production, entirely under the sway of capital. “It is all the same to the spoon-makers whether they work for hire at the master’s cost and on his premises, or are occupied in their own cottages, for in this industry, as in others, everything has been weighed, measured and counted. The spoon-maker never earns more than just enough to keep body and soul together.”[39] It is quite natural that under such conditions the capitalists who dominate the whole trade are in no hurry to open their own workshops, and the industry, based on hand skill and traditional division of labour, stagnates in its seclusion and immobility. Tied to the land, the “handicraftsmen” seem to have become petrified in their routine: as in 1879, so in 1889, they still count money in the old style, in banknotes and not in silver.

The toy industry in Moscow Gubernia is headed similarly by establishments of the capitalist-manufactory type.[40] Of 481 workshops, 20 have over 10 workers each. Division of labour, both as to wares and as to individual operations, is practised on a very wide scale, enormously raising the productivity of labour (at the cost of crippling the worker). For example, it is estimated that a small workshop yields a return of 26% of the selling price, and a big workshop, one of 58%.[41] Of course, the fixed capital of the big proprietors is also much larger; technical devices are met with (for example, drying sheds). The centre of the industry is a non-agricultural township, the suburb of Sergiyevsky (where there are 1,055 workers out of a total of 1,398, with an output to the amount of 311,000 rubles out of a total of 405,000 rubles; the population, according to the 1897 census, numbers 15,155). The author of the article on this industry, referring to the prevalence of small workshops, etc., considers it more, but still not very, likely that the industry will develop into manufacture rather than into factory industry. “In the future, too,” he says, “the small producers will always be able to compete more or less successfully with large-scale production” (loc. cit., 93). The author forgets that in manufacture the technical basis is always the same hand-production that obtains in the small industries; that the division of labour can never be such a decisive advantage that it will entirely eliminate the small producers, particularly if the latter resort to such means as lengthening the working day, etc.; and that manufacture is never in a position to embrace the whole of production, but remains a mere superstructure over the mass of small establishments.

The most extensive areas of the leather industry present particularly striking examples of the complete merging of “handicraft” and factory industry, examples of capitalist manufacture highly developed (in depth and in breadth). What is characteristic is the fact that the gubernias which are conspicuous for the size of their “factory” leather industry (Vyatka, Nizhni-Novgorod, Perm and Tver) are marked by a particular development of “handicraft” industries in this sphere.

In the village of Bogorodskoye, Gorbatov Uyezd, Nizhni-Novgorod Gubernia, there were, according to the Directory for 1890, 58 “factories” with 392 workers and an output totalling 547,000 rubles; according to the List for 1894-95 there were 119 “works,” with 1,499 workers on the premises and 205 outside, and with an output totalling 934,000 rubles (the latter figures covering only the processing of livestock produce, the principal local industry). But these data deal only with the top levels of capitalist manufacture. Mr. Karpov in 1879 computed in this village and its environs over 296 establishments, with 5,669 workers (a large number of whom worked at home for capitalists), and with an output totalling about 1,490,000 rubles[42] in the following industries: tanning, shingle-gluing, basket-weaving (for packing goods), harness-making, horse-collar-making, mitten-making and, standing by itself, pottery. The Zemstvo census of 1889 listed 4,401 industrialists for this district, and of 1,842 workers for whom detailed information is given, 1,119 work for hire in other people’s workshops and 405 work at home for masters.[43] “Bogorodskoye, with its population of 8,000, is a huge tannery in continuous operation.”[44] To be more precise, it is a “serial” manufactory controlled by a few big capitalists who buy the raw materials, tan the hides, and turn them into a variety of articles, hiring several thousand absolutely propertyless workers for the job and ruling over the small establishments.[45] This industry has had a very long existence, since the 17th century; particularly memorable in the industry’s history are the Sheremetevs (beginning of the 19th century), landlords who helped considerably to develop the industry and, incidentally, protected the proletariat, which came into existence here long ago, from the local rich. After 1861 the industry greatly developed, and particularly did big establishments grow at the expense of the small ones; centuries of industrial activity produced from among the population remarkably skilled craftsmen who have carried the trade all over Russia. The firmly-rooted capitalist relations have led to the separation of industry from agriculture: hardly any farming is done in Bogorodskoye village itself, which, on the contrary, divorces neighbouring peasants who move into this “town” from the land.[46] Mr. Karpov notes in this village “a complete absence of peasant characteristics among the inhabitants,” so that “you would never think you were in a village and not a town.” This village leaves Gorbatov and all the other uyezd towns of Nizhni-Novgorod Gubernia far behind, with the exception, perhaps, of Arzamas. It is “one of the considerable commercial and industrial centres in the gubernia, and its industry and commerce run into the millions.” “The radius of the industrial and commercial influence of Bogorodskoye is very wide; but most closely connected with the industry of Bogorodskoye is that of its environs within a radius of 10 to 12 versts. These industrial environs are, as it were, a continuation of Bogorodskoye itself.” “The inhabitants of Bogorodskoye do not in the least resemble the ordinary, raw muzhiks: they are artisans of the burgher type, shrewd, experienced people, who look down on the peasants. The manner of life and the ethical standards of the Bogorodskoye inhabitants are completely urban.” To this we must add that the industrial villages of Gorbatov Uyezd are marked by a relatively high level of literacy among the population. Thus, the percentage of literate and student men and women is, in the villages of Pavlovo, Bogorodskoye and Vorsma, 37.8% and 20% respectively, as against 21.5% and 4.4% in the rest of the uyezd (see Zemstvo statistical Material ).

Quite analogous (only on a smaller scale) are the relations in the leather-processing industries of the villages of Katunki and Gorodets (Balakhna Uyezd), Bolshoye Murashkino (Knyaginin Uyezd), Yurino (Vasil Uyezd), and Tubanayevka, Spasskoye, Vatras and Latyshikha in the same uyezd. These are similar non-agricultural centres with a “ring” of surrounding agricultural villages, and with similar diverse industries and numerous small establishments (and also workers in the home) subordinated to big entrepreneurs, whose capitalist workshops are occasionally included among “factories and works.”[47] Without going into statistical details, which will provide nothing new compared with what has already been said, let us merely quote the following extremely interesting description of the village of Katunki:[48]

“A certain patriarchal simplicity in the relations between masters and workmen, which, however, is not so noticeable at first sight and is, unfortunately (?), disappearing increasingly every year . . . testifies to the handicraft character of the industries (?). It is only recently that the factory character both of the industries and of the population has begun to be observed, under the influence, in particular, of the town, intercourse with which has been facilitated by the inauguration of the steamboat service. Today the village looks like a regular industrial township: there is no sign of agriculture whatever, the houses are built close together as in the towns; the fine brick houses of the rich, and alongside of them the miserable hovels of the poor; the long wooden and brick buildings of the factories crowded in the middle of the village — all this sharply distinguishes Katunki from the neighbouring villages and clearly points to the industrial character of the local population. The inhabitants themselves possess features of character that also call to mind the type of “factory hand” who has already taken shape in Russia: a certain showiness in house furniture, in clothes and manners, spendthrift habits of life in most cases, and little care for the morrow, a forwardness and often affectation in speech, a certain superciliousness towards the country yokel — all these features are possessed by them in common with all Russian factory people.”[49]

In the town of Arzamas, Nizhni-Novgorod Gubernia, the “factory” statistics listed in 1890 a total of 6 tanneries, employing 64 workers (Directory ); this is only a small fraction of the capitalist manufacture which embraces the fur, boot-making and other industries. The same factories employ workers in the home, both in the town of Arzamas (in 1878, estimated at 400) and in 5 suburban villages, where out of the 360 furrier households, 330 work for Arzamas merchants, using their materials and working 14 hours a day for 6 to 9 rubles per month[50]; that is why the furriers are pallid, feeble and degenerating folk. In the suburb of Viyezdnaya Sloboda, of the 600 boot-maker households, 500 work for masters, from whom they receive the cut-out leather. The industry is of long standing, being about 200 years old, and is still growing and developing. The inhabitants hardly engage in agriculture at all; their whole manner of life is purely urban, and they live “in grand style.” The same applies to the furrier villages mentioned above, the inhabitants of which “look down with disdain upon the peasant and call him a ‘country bumpkin’.”[51]

We find exactly the same thing in Vyatka Gubernia. The Vyatka and Slobodskoi uyezds are centres both of “factory” and of “handicraft” leather and fur trades. In the Vyatka Uyezd, the handicraft tanneries are concentrated on the outskirts of the town and “supplement” the industrial activities of the big works,[52] for example, by working for the big owners; working for the latter also, in the majority of cases, are the handicraft harness-makers and glue makers. The fur factory owners have hundreds working for them in the home, sewing sheepskins, etc. This is just a single capitalist manufactory with branches: sheepskin dressing and sheepskin-coat-making, leather and harness, etc. Still more striking are the relations existing in the Slobodskoi Uyezd (the centre of the industries is the suburb of Demyanka); here we see a small number of big factory owners[53] at the head of handicraft tanners (numbering 870), boot- and mitten-makers (855), sheepskin-dressers (940), and tailors (309 make short sheepskin coats to order from capitalists). Generally speaking, such organisation of the production of leather goods is evidently very widespread: thus, in the town of Sarapul, Vyatka Gubernia, the List gives 6 tanneries, also making footwear, which employ, in addition to 214 workers on the premises, 1,080 outside workers (p. 495). What would become of our “handicrafts men,” those representatives of “people’s” industry who are depicted in such bright hues by all sorts of Manilovs, if all the Russian merchants and factory owners were to compute with equal detail and precision the outside workers employed by them?[54]

Reference should be made here to the industrial village of Rasskazovo, Tambov Uyezd, Tambov Gubernia (population in 1897 was 8,283), a centre both of “factory” industry (cloth mills, soap-works, tanneries and distilleries) and of “handicraft” industry, the latter being closely connected with the former; and to the industries: tanning, felt-making (as many as 70 masters, and establishments employing from 20 to 30 workers), glue-making, boot-making, stocking knitting (there is not a household where stockings are not knit from wool that “buyers-up” give out by weight), etc. Near this village is the suburb of Belaya Polyana (300 households), celebrated for industries of the same kind. In Morshansk Uyezd, the centre of the handicraft industries is the village of Pokrovskoye-Vasilyevskoye, which is also the centre of factory industry (see Directory and Reports and Investigations, Vol. III). In Kursk Gubernia, noteworthy as industrial villages and centres of “handicraft” industries are the suburbs: Veliko-Mikhailovka (Novy Oskol Uyezd; population in 1897 was 11,853), Borisovka (Graivoron Uyezd — 18,071 inhabitants), Tomarovka (Belgorod Uyezd, 8,716 inhabitants), Miropolye (Sudzha Uyezd, over 10,000 inhabitants. See Reports and Investigations, Vol. I, Information for 1888-1889). In the same villages you will also find leather “works” (see Directory for 1890). The principal “handicraft” industry is leather and boot-making. It arose as far back as the first half of the 18th century and reached the peak of its development in the 60s of the 19th century having become “a stable organisation of a purely commercial character.” The whole business was monopolised by contractors, who bought the leather and gave it out to be processed by handicraftsmen. The railways destroyed this monopoly character of capital, and the capitalist contractors transferred their capital to more profitable undertakings. Today it is organised as follows: there are about 120 big entrepreneurs; they own workshops where wage-workers are employed, and also distribute work to homes; there are as many as 3,000 small independent masters (who, however, buy their leather from the big ones); there are 400 people who work at home (for the big masters), and as many wage-workers; then there are the apprentices. The total number of boot-makers is over 4,000. In addition, there are handicraft potters, icon-case makers, icon painters, table-cloth weavers, etc.

A highly characteristic and typical example of capitalist manufacture is the squirrel-fur industry in Kargopol Uyezd, Olonets Gubernia, described with such knowledge of the facts, and with truthful and artless presentation of the whole life of the industrial population by a craftsman and teacher in the Transactions of the Handicraft Commission (Vol. IV). According to his description (in 1878), the industry has existed since the beginning of the 19th century: 8 masters employ 175 workers, in addition to which they have as many as 1,000 seamstresses and some 35 families of furriers working for them at home (in different villages), 1,300 to 1,500 persons in all, with an output totalling 336,000 rubles. As a point of interest, it should be noted that when this was a flourishing industry it was not included in the “factory” statistics. The Directory for 1879 makes no mention of it. But when it began to decline the statistics included it. The Directory for 1890 listed for the town and the uyezd of Kargopol 7 works, with 121 workers and an output totalling 50,000 rubles, whereas the List gave 5 works, with 79 workers (plus 57 outside) and an output totalling 49,000 rubles.[55] The order of things prevailing in this branch of capitalist manufacture is very instructive as a specimen of what goes on in our age-old, purely native “handicraft industries,” that have been left stranded in one of Russia’s numerous rural backwoods. The craftsmen work 15 hours a day in a very unhealthy atmosphere and earn 8 rubles per month, less than 60 or 70 rubles per year. The masters’ incomes amount to about 5,000 rubles per annum. The relations between masters and workers are “patriarchal”: according to ancient custom, the master gives the workers kvass and salt gratis, which they have to beg from his cook. As a mark of gratitude to the master (for “giving” them work) the workers come, without pay, to pull squirrel tails, and also clean furs after work. The workers live in the workshop all the week, and the masters knock them about, seemingly in a joke (p. 218, loc. cit.), make them do all sorts of jobs, such as raking hay, shovelling snow, fetching water, rinsing clothes, etc. Labour is astonishingly cheap in Kargopol itself, and the peasants in the vicinity “are ready to work for next to nothing.” Work is done by hand, there is systematic division of labour, and there is a lengthy apprenticeship (8 to 12 years); the lot of the apprentices can easily be imagined.

A particularly noteworthy example of capitalist manufacture is the celebrated boot industry of the village of Kimry, Korcheva Uyezd, Tver Gubernia, and its environs.[56] The industry is a very old one, having existed since the 16th century. Since the Reform, it has continued to grow and develop. In the early 70s Pletnev counted 4 volosts in the area covered by this industry, but in 1888 the area included 9 volosts. Basically the organisation of the industry is as follows. It is headed by the owners of big workshops employing wage-workers; they distribute the cut-out leather to be made up by outside workers. Mr. Pletnev counted 20 such masters, employing 124 adults and 60 boys, with an output totalling 818,000 rubles, while the number of workers occupied at home for these capitalists is estimated by the author approximately at 1,769 adults and 1,833 boys. Then come the small masters, each with 1 to 5 wage-workers and 1 to 3 boys. These masters dispose of their goods mainly in the village market in Kimry; they number 224 and have 460 adults and 301 boys working for them; output totals 187,000 rubles. Hence, there are 244 masters altogether, employing 2,353 adults (of whom 1,769 work at home) and 2,194 boys (of whom 1,833 work at home), with an output totalling 1,005,000 rubles. Further, there are workshops which do various individual operations: currying (skin-cleaning with scraper); chipping (gluing of chips left from currying); special carting (4 masters, with 16 employees and up to 50 horses); special carpentry (box-making), etc.[57] Pletnev calculated the total output at 4.7 million rubles for the whole district. In 1881 the number of handicraftsmen was computed at 10,638, and with migrants, 26,000, with an output totalling 3.7 million rubles. As to conditions of labour, it is important to note the excessively long working day (14 to 15 hours) and the extremely insanitary working conditions, payment in goods, etc. The centre of the industry, Kimry village, “is more like a small town” (Reports and Investigations, I, 224); the inhabitants are poor agriculturists, and are engaged in their industry all the year round; only the rural handicraftsmen give up the industry during haymaking. The houses in Kimry village are urban, and the inhabitants are distinguished for their urban habits of life (such as “showiness”). Until very recently this industry was not included in “factory” statistics, probably because the masters “readily style themselves handicraftsmen” (ibid., 228). The List has for the first time included 6 boot workshops in Kimry district, with 15 to 40 workers each on the premises, and with no outside workers. Of course, it contains no end of gaps.

Manufacture also includes the button industry of Moscow Gubernia, Bronnitsi and Bogorodskoye uyezds — the making of buttons from hoofs and rams’ horns. Engaged in this industry are 487 workers, employed in 52 establishments; the output totals 264,000 rubles. Establishments with fewer than 5 employees number 16; those with 5 to 10 — 26; those with 10 and more — 10. Masters who do without wage-workers number only 10; these work for big masters, using the latter’s materials. Only the big industrialists (who, as is evident from the figures given, should have from 17 to 21 workers per establishment) are quite independent. It is they, evidently, who figure in the Directory as “factory owners” (see p. 291: 2 establishments with an output totalling 4,000 rubles and with 73 workers). This is “serial manufacture”; the horns are first steamed in what is called the “smithy” (a wooden hut with a furnace); then they are passed on to the workshop where they are cut up, after which they go to a stamping press, where the pattern is imprinted, and, lastly, are finished and polished on lathes. The industry has its apprentices. The working day is 14 hours. Payment in goods is a regular thing. The relations between masters and men are patriarchal, as seen in the following: the master calls the workers “boys,” and the pay-book is called the “boys’ book”; when the master pays the workers, he lectures them and never grants in full their “requests” for payment.

The horn industry, which is included in our table of small industries (Appendix I to Chapter V, Industries Nos. 31 and 33), is also of the same type. “Handicraftsmen” employing dozens of wage-workers figure also in the Directory as “factory owners” (p. 291). Division of labour is practised; work is also given out to home workers (horn trimmers). The centre of the industry in Bogorodsk Uyezd is the big village of Khoteichi, where agriculture is receding into the background (population in 1897 was 2,494). The Moscow Zemstvo publication stated quite rightly: Handicraft Industries of Bogorodsk Uyezd, Moscow Gubernia, in 1890, that this village “is nothing but a large comb manufactory ” (p. 24, our italics). In 1890, over 500 industrialists were counted in this village, with an output of from 3.5 to 5.5 million combs. “More often than not, the horn dealer is also a buyer-up of finished goods, and in many cases a big comb-maker as well.” The position of those makers who are compelled to take horns “at piece rates” is particularly bad: “their position is actually worse than that of the wage-workers in the big establishments.” Dire need compels them to exploit the labour of their whole families beyond measure, to lengthen their working day and to put juveniles to work. “During the winter, work in Khoteichi starts at one o’clock in the morning, and it is hard to say for certain when it ends in the cottage of the ‘independent’ craftsman doing ‘piece-work.’” Payment in goods is widely practised. “This system, eliminated with such difficulty from the factories, is still in full force in the small handicraft establishments” (27). Probably, the horn goods industry is organised on similar lines in Kadnikov Uyezd, Vologda Gubernia, in the area of Ustye village (known as “Ustyanshchina”), where there are 58 hamlets. Mr. V. Borisov (Transactions of the Handicraft Commission, Vol. IX) counts 388 handicraftsmen here, with an output totalling 45,000 rubles; all the handicraftsmen work for capitalists, who buy horns in St. Petersburg and tortoise-shell abroad.

At the head of the brush industry in Moscow Gubernia (see Appendix I to Chapter V, Industry No. 20) we find big establishments with a large number of wage-workers and with systematic division of labour.[58] It is interesting to note at this point the changes that took place in the organisation of this industry between 1879 and 1895 (see Moscow Zemstvo publication: The Brush Industry According to the Investigation of 1895 ). Some well-to-do industrialists went to Moscow to carry on the industry there. The number of industrialists increased 70%, the increase being particularly large in the number of women (+170%) and girls (+159%). The number of big workshops with wage-workers diminished: the proportion of establishments with wage-workers dropped from 62% to 39%. This was due to the fact that the masters began to distribute work to be done in the home. The introduction into general use of the drilling machine (for making holes in brush blocks) accelerated and facilitated one of the main processes in brushmaking. The demand for “setters” (craftsmen who “set” bristle in the block) increased; and this operation, which became increasingly specialised, fell to the lot of women, their labour being cheaper. The women began to work at home setting bristle, and were paid by the piece. Thus, the growing resort to domestic industry was caused in this case by progress in technique (drilling machine), progress in division of labour (the women do nothing but set bristle), and progress in capitalist exploitation (the labour of women and girls being cheaper). This example shows very clearly that domestic industry by no means eliminates the concept of capitalist manufacture, but, on the contrary, is sometimes even a sign of its further development.

In the section relating to ceramics we get an example of capitalist manufacture in the industries of the Gzhel district (an area of 25 villages Bronnitsi and Bogorodskoye uyezds, Moscow Gubernia). The relevant statistics are given in our table of small industries (Appendix I to Chapter V, Industries Nos. 15, 28 and 37). From these data it is evident that despite the enormous differences between the three Gzhel industries: pottery, porcelain and decorative, these differences disappear as we pass from one grade of establishment to another in each industry, and we get a series of workshops of successively increasing dimensions. Here are the average numbers of workers per establishment according to grade in these three industries: 2.4 — 4.3 — 8.4 — 4.4. — 7.9 — 13.5 — 18 — 69 — 226.4. In other words, the workshops range from the very smallest to the very biggest. There is no doubt that the big establishments belong to the category of capitalist manufacture (inasmuch as they have not introduced machines, have not developed into factories); what is important, however, is not only this, but also that the small establishments are connected with the big ones ; that we have a single system of industry here and not separate workshops of one or other type of economic organisation. “Gzhel constitutes a single economic whole” (Isayev, loc. cit., 138), and the big workshops in the district have grown slowly and gradually out of the small ones (ibid., 121). The work is done by hand,[59] with considerable division of labour : among the potters we find wheel hands (specialising in different sorts of pottery), kilnmen, etc., and sometimes special workers for preparing colours. In the manufacture of porcelain-ware division of labour is extremely detailed: crushers, wheel hands, feeders, kilnmen, decorators, etc. The wheel hands even specialise in the various kinds of porcelain ware (cf. Isayev, loc. cit., 140: in one case division of labour increases productivity of labour by 25%). The decorators’ shops work for the porcelain makers and are, therefore, only departments of the latter’s manufactories, performing a special detailed operation. It is characteristic of developed capitalist manufacture that physical strength itself becomes a specialty. Thus, in Gzhel, some of the villages are engaged (almost to a man) in clay digging; for heavy work not requiring special skill (grinding), workers from the Tula and Ryazan gubernias are employed almost exclusively, being superior in strength and vigour to the not very robust Gzhelians. Payment in goods is widely practised. Agriculture is in a bad way. “The Gzhelians are a degenerating race” (Isayev, 168) — weak-chested, narrow-shouldered, feeble; the decorators lose their sight at an early age, etc. Capitalist division of labour breaks up the worker and deforms him. The working day is from 12 to 13 hours.

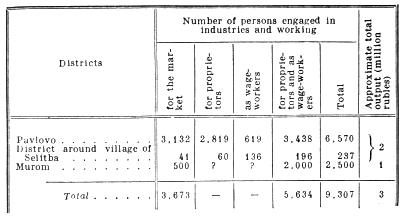

The celebrated Pavlovo lock and cutlery industries cover the whole of Gorbatov Uyezd, Nizhni-Novgorod Gubernia, and Murom Uyezd, Vladimir Gubernia. These industries originated very long ago. Smirnov states that as far back as 1621 there were (according to the cadastres[91]) 11 smithies in Pavlovo. By the middle of the 19th century these industries constituted a far-flung network of fully developed capitalist relations. After the Reform, the industries in this district continued to develop and expand. According to the Zemstvo census of 1889, in Gorbatov Uyezd 13 volosts and 119 villages were engaged in industry; a total of 5,953 households, 6,570 male workers (54% of the total number working in these villages) and 2,741 old men, juveniles and women, 9,311 persons in all. In the Murom Uyezd, Mr. Grigoryev in 1881 registered 6 industrial volosts, 66 villages, 1,545 households and 2,205 male workers (39% of the total number working in these villages). Not only were large, non-agricultural industrial villages formed (Pavlovo, Vorsma), but even the surrounding peasants were diverted from agriculture: outside of Pavlovo and Vorsma, in Gorbatov Uyezd, 4,492 persons were engaged in industries, of whom 2,357, or more than half did not engage in agriculture. Life in centres like Pavlovo has become quite urban and has given rise to incomparably more developed requirements, more cultured environment, clothes, manner of life, etc., than among the surrounding “raw” peasants.[60]

Turning to the economic organisation of the Pavlovo industries, we must first of all note the indubitable fact that the “handicraftsmen” are headed by the most typical capitalist manufactories. For example, in the Zavyalovs’ establishment (which already in the 60s employed over 100 workers at the bench and has now introduced a steam engine) a penknife passes through 8 or 9 hands: the forger, blade-maker, handle-maker (usually an outside worker), hardener, facer, polisher, finisher, grinder and marker. This is extensive capitalist co-operation based on division of labour, with a considerable number of the workers performing individual operations employed at home and not in the capitalist’s workshop. Here are facts given by Mr. Labzin (in 1866) on the bigger establishments in the villages of Pavlovo, Vorsma and Vacha, covering all branches of production in this district: 15 proprietors had 500 workers occupied on the premises and 1,134 workers outside, making a total of 1,634, with an output totalling 351,700 rubles. How far this description of economic relations is applicable to the whole district at the present time may be seen from the following data[61]:

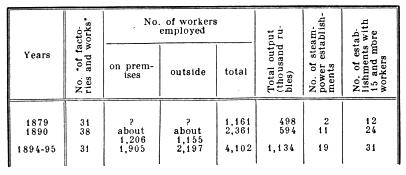

Thus, the organisation of the industry as outlined by us prevails in all the districts. All in all, about three-fifths of the total number of workers are employed capitalistically. Here too, consequently, we find manufacture predominating in the general structure of the industry[62] and holding masses of workers under its sway, without, however, being able to eradicate small production. The relative tenacity of the latter is fully explained, firstly, by the fact that in some branches of the Pavlovo industry mechanised production has not yet been introduced at all (for instance, in lock-making); and, secondly, by the fact that the small producer tries to save himself from sinking by resorting to means that cause him to sink far lower than the wage-worker. These means are: lengthening the working day, and reducing the standard of living and of general requirements. “The earnings of the group of handicraftsmen who work for proprietors are less subject to fluctuation” (Grigoryev, loc. cit., 65); at Zavyalovs’, for example, the lowest-paid worker is the handle-maker; “he works at home, and that is why he is satisfied with lower earnings” (68). The handicraftsmen who work “for factory owners” are “able to earn somewhat more than the average earnings of the one who takes his products to the market. Larger earnings are particularly noticeable among the workers who live in the factories” (70).[63] The working day in the “factories” is from 14 1/2 to 15 hours, with a maximum of 16 hours. “The working day of the home-working handicraftsmen, on the other hand, is never less than 17 hours and sometimes as much as 18 and even 19 hours” (ibid.). It would not be in the least surprising if the law of June 2, 1897[92] caused an increase here in home-work; it is high time these “handicraftsmen” directed their efforts towards compelling the proprietors to organise factories! Let the reader also recall the notorious Pavlovo “loan-purchase,” “exchange,” “wife-pawning” and similar forms of bondage and personal degradation which grind down the quasi-independent small producer.[64] Fortunately, rapidly developing large-scale machine industry does not so readily tolerate these worst forms of exploitation as manufacture does. Running ahead a little, let us quote data on the growth of factory production in this district.[65]

We thus see that ever-increasing numbers of workers are being drawn into large establishments, which are going over to the use of machines.[66]

The industries of Bezvodnoye village, Nizhni-Novgorod Gubernia and Uyezd also come under the head of capitalist manufacture. This is also an industrial village, the majority of whose inhabitants do not engage in agriculture at all, and which serves as the centre of an industrial area of several villages. According to the Zemstvo census of 1889 (Material, Vol. VIII, Nizhni-Novgorod, 1895), in the Bezvodnoye Volost (581 households) 67.3% of the households cultivated no land, 78.3% had no horses, 82.4% engaged in industries, and 57.7% had literate persons and schoolchildren in the family (as against an average for the uyezd of 44.6%). The Bezvodnoye industries are devoted to the production of various metal goods: chains, fish-hooks, and metal fabrics; the output was estimated at 2 1/2 million rubles in 1883[67] and 1 1/2 million rubles in 1888-89.[68] The organisation of the industry is as follows: work for proprietors, using their materials, which is distributed among a number of workers performing single operations and done partly in the employers’ workshops and partly in the home. For example, in the making of fish-hooks the various operations are performed by “benders,” “cutters” (who work in a special shed) and “pointers” (women and children who sharpen the hook-points in their homes); all these work at piece rates for the capitalist, while the bender gives out work on his own account to the cutters and pointers. “Metal wire is now done by horse-driven windlasses; formerly the wire was drawn by blind men, who were brought here in large numbers. . . .” One of the “specialities” of capitalist manufacture! “The conditions under which this work is done differ very much from those in all the other trades. People have to work in a stifling atmosphere filled with the harmful vapours emanating from accumulated horse dung.”[69] Organised on the same lines of capitalist manufacture are the screen,[70] the pin,[71] and the gold-thread industries.[72] In the last-named industry at the beginning of the 80s there were 66 establishments, employing 670 workers (of whom 79% were hired), with an output totalling 368,500 rubles; some of these capitalist establishments were occasionally also included among the “factories and works.”[73]

The locksmith industries of the Burmakino Volost (and surrounding volosts) of Yaroslavl Gubernia and Uyezd are probably organised on the same lines. At all events, here we observe the same division of labour (blacksmiths, blowers and locksmiths), the same extensive development of wage-labour (of 307 smithies in the Burmakino Volost, 231 employ wage-workers), the same predominance of big capital over all these detail workers (the buyers-up are at the top; the blacksmiths work for them, and the locksmiths for the blacksmiths), the same combination of the buying up of wares with the production of wares in capitalist workshops, some of which are occasionally included among the “factories and works.”[74]

In the appendix to the preceding chapter, statistics were given on the tray and the copper industries[75] of Moscow Gubernia (the latter in the district known as “Zagarye”). The data show that wage-labour plays a predominant part in these industries, that the industries are headed by large workshops employing an average of from 18 to 23 wage-workers per establishment, with an average output of from 16,000 to 17,000 rubles. If we add to this that division of labour is very widely practised here,[76] it will be clear that what we have is capitalist manufacture.[77] “The small industrial units, which are an anomaly under the existing conditions of technique and division of labour, can only hold out alongside the big workshops by lengthening the working day to the utmost” (Isayev, loc. cit., p. 33) — among the tray-makers, for example, for as long as 19 hours. The ordinary working day here is from 13 to 15 hours; with the small proprietors it is from 16 to 17 hours. Payment in goods is widely practised (both in 1876 and in 1890).[78] Let us add that the lengthy existence of this industry (it arose at the beginning of the 19th century, at the latest) and extensive specialisation have, in this case too, produced highly skilled workers; the Zagarians are famed for their craftsmanship. Specialities have also sprung up in the industry which need no preliminary training and are within the grasp of even under-age workers. “This very possibility,” Mr. Isayev rightly observes, “of becoming an under-age worker at once and acquiring a trade, as it were, without having to study, indicates that the handicraft spirit, which demands the training of labour-power, is disappearing; the simplicity of many of the detailed operations is a symptom of the transition of handicraft to manufacture” (loc. cit., 34). Let us only observe that to a certain degree the “handicraft spirit” always remains in manufacture, for its basis is the same hand production.

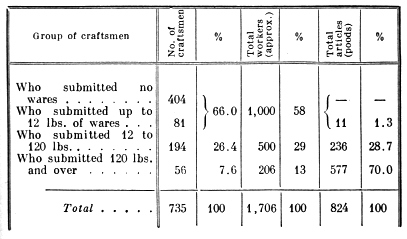

The village of Krasnoye, Kostroma Gubernia and Uyezd, is one of the industrial villages usually held up as centres of our “people’s” capitalist manufacture. This large village (in 1897 it had 2,612 inhabitants) is purely urban in character; the inhabitants live like townspeople and (with very few exceptions) do not engage in agriculture. Krasnoye is the centre of the jewellery industry which covers 4 volosts and 51 villages (including Sidorovskoye Volost of Nerekhta Uyezd), and in them 735 households and about 1,706 workers.[79] “The principal representatives of industry,” said Mr. Tillo, “are undoubtedly the big industrialists of the village of Krasnoye: the Pushilovs, Mazovs, Sorokins, Chulkovs and other merchants. They buy materials (gold, silver and copper), employ craftsmen, buy up finished articles, distribute orders for work to be done in the home, supply samples, etc.” (2043). The big industrialists have their workshops, so-called “rabotorni” (laboratories), where the metal is smelted and forged, then to be given out for finishing to “handicraftsmen”; they have technical appliances, such as “pretsi” (presses and dies for stamping), “punches” (for embossing designs), “rollers” (for stretching the metal), benches, etc. Division of labour is widely practised: “Nearly every article passes through several hands in an established order in the course of manufacture. For example, in the making of ear-rings, the master industrialist first sends the silver to his own workshop, where part of it is rolled and part drawn into wire; then on receipt of an order the material is given to a craftsman who, if he has a family, divides the work among several persons; one uses a punch to cut the silver plates into the shapes for the ear-rings, another bends the wire into the rings with which the ear-rings are attached to the ears, a third solders these parts, and, lastly, a fourth polishes the finished ear-rings. None of this work is difficult, or requires much training; very often the soldering and the polishing are done by women and by children of 7 or 8 years of age” (2041).[80] Here, too, the working day is excessively long, usually as much as 16 hours. Payment in provisions is common.

The following statistics (published quite recently by a local assay inspector) clearly illustrate the economic structure of the industry:[93]

“Both the first groups (about two-thirds of the total number of craftsmen) should be classed as home-working factory workers rather than as handicraftsmen.” In the top group “wage-labour occurs more and more frequently. . . . The craftsmen have begun to buy articles made by others”; in the upper strata of this group “buying-up predominates,” and “four of the buyers-up have no workshops at all.”[81]

The samovar and accordion industries in Tula town and environs are highly typical examples of capitalist manufacture. Generally speaking, the “handicraft” industries in this district have a long history, dating back to the 15th century.[82] They evidenced a particularly rapid development in the middle of the 17th century; Mr. Borisov considers that the second period in the development of the Tula industries then began. In 1637 the first iron foundry was built (by the Dutchman Vinius). The Tula gunsmiths formed a separate smiths’ suburb, constituted a separate social estate, enjoying special rights and privileges. In 1696 the first iron foundry was erected in Tula by a famous Tula blacksmith, and the industry spread to the Urals and Siberia.[83] Then began the third period in the history of the Tula industries. The craftsmen set up their own workshops and taught the trade to surrounding peasants. In the 1810s and 1820s the first samovar factories were started. “By 1825 there were in Tula 43 different factories that belonged to gunsmiths, while those in existence at the present time nearly all belong to one-time gunsmiths, now Tula merchants” (loc. cit., 2262). Here, consequently, we observe a direct continuity and connection between the old guild masters and the principals of subsequent capitalist manufacture. In 1864 the Tula gunsmiths were freed from serf dependence[94] and assigned to the burgher estate; earnings dropped as a consequence of the severe competition of the village handicraftsmen (which caused a reverse flow of industrialists from town to country); the workers turned to the samovar, lock, cutlery, and accordion industries (the first Tula accordions appeared in 1830-1835).

The samovar industry is at present organised as follows. It is headed by big capitalists who own workshops employing tens and hundreds of wage-workers, but they also distribute many separate operations to be done by workers, urban and rural, in their homes; those who perform these operations sometimes still have their own workshops and employ wage-workers. Naturally, side by side with the big there are small workshops, with all the consecutive stages of dependence upon the capitalists. Division of labour is the general basis of the whole structure of this trade. The process of samovar-making is divided into the following separate operations: 1) rolling the copper sheets into tubes (tubing); 2) soldering the tubes; 3) filing the seams; 4) fitting the bottoms; 5) beating out the shapes; 6) cleaning the insides: 7) turning the bodies and necks; 8) plating; 9) press-punching the vents in the bottoms and the covers; 10) assembling the samovars. Further, there are the separate processes of casting the small copper parts: a) preparing the moulds and b) casting.[84] Where work is given out to be done in the home, each of these operations may constitute a special “handicraft” industry. One of these “industries” was described by Mr. Borisov in Vol. VII of the Transactions of the Handicraft Commission. This industry (samovar tubing) consists in peasants doing at piece rates one of the operations we have described, using merchants’ materials. The handicraftsmen left Tula town to work in the countryside after 1861; the cost of living and standard of requirements were lower in the countryside (loc. cit., p. 893). Mr. Borisov quite rightly attributes this tenacity of the “handicraftsman” to the retention of hand-labour in the beating out of samovars; “it will always be profitable for the manufacturer to employ the village handicraftsman, because he works at from 10 to 20% below the rate of the urban artisan” (916).

Mr. Borisov estimated the value of the output of samovars in 1882 at approximately 5 million rubles, the number of workers (handicraftsmen included) totalling from 4,000 to 5,000. In this case also the factory statistics cover only a fraction of capitalist manufacture. The Directory for 1879 counted in Tula Gubernia 53 samovar “factories” (all hand-operated) with 1,479 workers and an output totalling 836,000 rubles. The Directory for 1890 gives 162 factories, 2,175 workers, and an output of 1.1 million rubles; the list of firms, however, contains only 50 factories (1 steam operated), with 1,326 workers and an output totalling 698,000 rubles. Evidently, some hundred small establishments were in this case classed as “factories.” Lastly, the List gives the following for 1894-95: 25 factories (4 steam-operated), 1,202 workers (+ 607 outside), and an output totalling 1,613,000 rubles. In these data neither the number of factories nor the number of workers are comparable (for the reason given above, and also because of the lumping together in previous years of workers on the premises and outside). The only thing beyond doubt is that manufacture is being steadily displaced by large-scale machine industry: in 1879, there were 2 factories with 100 and more workers; in 1890 there were 2 (one steam-operated) and in 1894-95 there were 4 (three steam-operated).[85]

The accordion industry, which is at a lower stage of economic development, is organised in precisely the same way.[86] “In the making of accordions there are over ten separate trades” (Transactions of the Handicraft Commission, IX, 236); the making of the different parts of an accordion or the performance of some of the operations constitute separate, quasi-independent “handicraft” industries. “When things are quiet all the handicraftsmen work for factories or for more or less big workshops, the owners of which supply them with materials; when, however, there is a brisk demand for accordions, a large number of small producers appear, who buy up parts from the handicraftsmen, assemble them and take the finished articles to the local shops where accordions are very readily purchased” (ibid.). Mr. Borisov in 1882 estimated from 2,000 to 3,000 workers in this industry, with an output totalling about 4 million rubles; factory statistics in 1879 showed two “factories,” with 22 workers and an output totalling 5,000 rubles; in 1890, 19 factories, with 275 workers and an output totalling 82,000 rubles; in 1894-95 one factory, with 23 workers (plus 17 outside) and an output totalling 20,000 rubles.[87] Steam-engines are not employed at all. All these figure variations indicate a purely haphazard picking of individual establishments which are component parts of the complex organism of capitalist manufacture.

[1] Cf. Statistical Returns for Moscow Gubernia, Vol. VII, Pt. III (Moscow, 1883), pp. 63-64.—Lenin

[2] For a list of the most important towns of this type, see next chapter.—Lenin

[3] Examples of such confusion will be given in the next chapter.—Lenin

[4] See Industries of Vladimir Gubernia, III. It would be impossible and superfluous to give detailed data on all the weaving industries described in the literature on our handicraft industry. Moreover, in the majority of these industries the factory now reigns supreme. On the subject of “handicraft weaving” see also Statistical Returns for Moscow Gubernia, Vols. VI and VII. — Transactions of the Handicraft Commission — Material on Hand-Labour Statistics.[95] — Reports and Investigations. — Korsak, loc. cit.—Lenin

[5] The Military Statistical Abstract managed to count in Vladimir Gubernia, in 1866, 98 silk factories (!) with 98 workers and a total output of 4,000 rubles(!). The Directory for 1890 gives 35 factories, 2,112 workers, and 936,000 rubles. According to the List for 1894-95 there were 98 factories, 2,281 workers, with an output of 1,918,000 rubles, and in addition, 2,477 workers “outside of establishments, on the side.” Just try to distinguish “handicraftsmen” here from “factory workers”!—Lenin

[6] According to the Directory for 1890 there were outside of Moscow 10 galloon factories, with 303 workers and an output totalling 58,000 rubles. But according to Statistical Returns for Moscow Gubernia (Vol. VI, Pt. II), there were 400 establishments, with 2,619 workers (of whom 72.8% were wage-workers) and with an output totalling 963,000 rubles.—Lenin

[7] The Collection of Factory Inspectors’ Reports for 1903 (St. Petersburg, 1906) states that in Saratov Gubernia there were 33 distributing offices with 10,000 workers. (Note to 2nd edition.)—Lenin

[8] The centre of this industry is Sosnovka Volost, where the Zemstvo census of 1886 counted 4,626 households, with a population of 38,000 persons of both sexes; 291 industrial establishments. Altogether in the volost 10% of the households were houseless (as against 6.2% in the uyezd), and 44.5% of the households cultivated on land (as against 22.8% in the uyezd). See Statistical Returns for Saratou Gubernia, Vol. XI. — Capitalist manufacture has, consequently, created industrial centres here too which divorce the workers from the land.—Lenin

[9] The sources are shown in the text. The number of establishments is about half the number of independent workers (52 establishments in Vasilyev Vrag, 5 + 55 + 110 in Krasnoye village and 21 establishments in the 4 small villages). On the other hand, the figures for the town of Arzamas and Viyezdnaya Sloboda stands for the number of “factories,” and not of workers.—Lenin

[10] Let us note that the diagram given is typical of all Russian industries organised on the lines of capitalist manufacture: everywhere at the head of the industry we find big establishments (sometimes classed among “factories and works”), and a mass of small establishments completely under their sway — in a word, capitalist co-operation based on division of labour and hand production. Non-agricultural centres are formed by manufacture in exactly the same way, not only here, but also in the majority of other industries.—Lenin

[11] They are naked as they work in a temperature of 22°r; to 24°r; Réaumur. The air is full of fine and also coarse dust, wool and other stuff. The floors in the “factories” are earthen (in the washing sheds of all places), etc.—Lenin

[12] It is not without interest to note here the specific jargon of the inhabitants of Krasnoye; this is characteristic of the territorial isolation peculiar to manufacture. “In the village of Krasnoye factories are given the Matroisk name of povarnyas (lit. kitchens —Ed.). . . . Matroisk is one of the numerous branches of the Ophen dialect, the three main branches of which are Ophen proper, spoken mainly in Vladimir Gubernia; Galivon, in Kostroma Gubernia; and Matroisk, in the Nizhni-Novgorod and Vladimir gubernias” (Transactions of the Handicraft Commission, V, p 465). Only large-scale machine industry completely destroys the local character of social ties and replaces them by national (and international) ties.—Lenin

[13] Material for Evaluation of the Lands of Nizhni-Novgorod Gubernia, Vol. XI, Nizhni-Novgorod, 1893, pp. 211-214.—Lenin

[14] Transactions of the Handicraft Commission, VI.—Lenin

[15] Reports and Investigations, III.—Lenin

[16] Industries of Vladimir Gubernia, Vol. II.—Lenin

[17] Industries of Vladimir Gubernia, Vol. II, p. 271.—Lenin

[18] See Appendix I to Chapter V, Industry No. 27.—Lenin

[19] Some of these establishments were occasionally included among “factories and works.” See, for example, the Directory for 1879, p.126.—Lenin

[20] See above, Chapter V, § VII.—Lenin

[21] Statistical Returns for Moscow Gubernia, IV, Pt.I, pp. 282-287.—Lenin

[22] See Transactions of the Handicraft Commission, IX, and Reports and Investigations, III.—Lenin

[23] By some accident, such workshops have not yet been included among “factories and works.”—Lenin

[24] Transactions of the Handicraft Commission, II.—Lenin

[25] According to Zemstvo statistics (Vol. VII of Material, Nizhni-Novgorod, 1892) in these villages in 1889 there were 341 and 119 households, numbering respectively 1,277 and 540 persons of both sexes. There were 253 and 103 allotment households. Households participating in industries numbered 284 and 91, of which 257 and 32 did not engage in agriculture. There were 218 and 51 horseless households. Those leasing their allotments numbered 237 and 53.—Lenin

[26] Cf. Nizhni-Novgorod Handbook, Vol IV, article by Rev. Roslavlev.—Lenin

[27] Sketch of Condition of Handicraft Industry in Perm Gubernia, p. 158; in the table totals there is a mistake or a misprint.—Lenin

[28] Ibid., pp. 40 and 188 of table. To all appearances these same establishments also figure in the List, p. 152. For the purpose of comparing the big establishments with the small ones we have singled out the agriculturist commodity-producers, see Studies, p. 156. (See present edition, Vol. 2, The Handicraft Census of 1894-95 in Perm Gubernia. —Ed.)—Lenin

[29] The Handicraft Industries of Perm Gubernia at the Siberian Urals Exhibition, Pt. III, p. 47 and foll.—Lenin

[30] See Zemstvo statistical returns for Trubchevsk, Karachev and Orel uyezds of Orel Gubernia. The connection between the big manufactories and the small peasant establishments is also evident from the fact that the employment of wage-labour develops in the latter as well: for example, in Orel Uyezd, 16 peasant master spinners employ 77 workers.—Lenin

[31] V. Ilyin, Studies, p. 176. (See present edition, Vol.2, The Handicraft Census of 1894-95 in Perm Gubernia. —Ed.)—Lenin

[32] See precise data on Perm handicraft census about this, ibid., p. 177 (See present edition, Vol. 2, The Handicraft Census of 1894-95 in Perm Gubernia. —Ed.)—Lenin

[33] See Directory and List on Perm Gubernia and the village of Nevyansky Zavod (non-agricultural), which is the centre of this “handicraft industry.”—Lenin

[34] Cf. our Studies, pp. 177-178. (See present edition, Vol. 2, The Handicraft Census of 1894-95 in Perm Gubernia. —Ed.)—Lenin

[35] Reports and Investigations, I.—Lenin

[36] Reports and Investigations, III.—Lenin

[37] There are 14 big timber merchants. These have timber-seasoning rooms (costing about 300 rubles), of which there are 24 in the village, each employing 6 workers. These merchants also give out materials to workers, whom they get into their grip by advancing them money.—Lenin